Seam tracking of curved pipe tube multi- track welding in one time

| --Share to Friend--- |

Seam tracking of curved pipe tube multi- track welding in one time

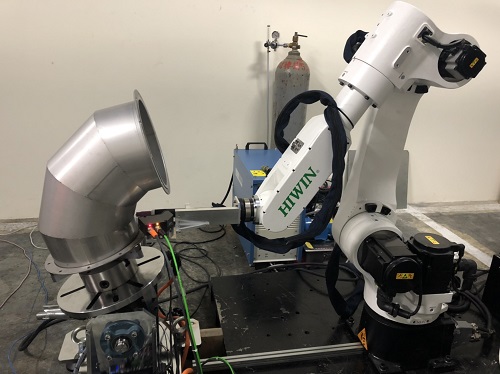

1. Enter the relevant parameters (weld pipe diameter, bending angle, number of weld beads...) to let the computer calculate the welding path 2. Calculate the relative position to the robot arm with TIG welding head 3. Laser Scanner scan to create 3D weld seam position 4. The robot arm follows the welding position and performs TIG welding 5. With SANYODENKI dual servo motor control positioning plate to assist the robot arm to deal with the problem of welding dead angle of curved pipe 6. Multi-weld tracking welding operation can be performed at one time

View Video: Seam tracking of curved pipe tube multi- track welding in one time

Please contact us for any inquiries, thank you. E-mail: sales@quadrep.com.tw |

| --Go Back--- |